Ever wondered what keeps a fast-moving electronics production line running smoothly? It's not just the main machines—PCB Storage Machines play a vital role too. In today's electronics manufacturing, proper PCB storage helps prevent delays, protect components, and improve quality.

In this post, you'll learn what a PCB Storage Machine is, why it matters, and how it boosts efficiency across SMT and DIP lines.

What Is a PCB Storage Machine and How Does It Work?

A PCB storage machine is a special type of equipment used in electronics manufacturing lines. You can think of it as a smart shelf that holds printed circuit boards while they wait for the next process. It doesn't just store boards randomly—it knows when to release or hold them, depending on how fast the machines before and after it are working. This makes sure that the whole line runs smoothly without stops or slowdowns.

In SMT and DIP lines, not all machines work at the same pace. For example, the pick-and-place machine might finish its job quicker than the reflow oven. If there's no space to hold the extra boards, things can get jammed up fast. That's where a PCB storage machine comes in. It acts like a traffic controller, keeping the flow balanced by holding boards temporarily until the next machine is ready.

Inside the machine, there's usually a lift that moves up and down to stack or release boards. This lift is often powered by a servo motor for accurate positioning. A PLC (programmable logic controller) handles all the instructions, making sure the timing is just right. Sensors watch the boards move in and out, helping to prevent crashes or jams. Some machines also let you see how many boards are inside, thanks to display screens or transparent panels.

This kind of buffer storage is key when you need different machines to work together. If the machine behind needs a board but the one in front is still busy, the storage machine can quickly step in and supply a board from its stack. Or if the front machine finishes but the back is slow, it can hold the board for a few moments. That way, everything keeps running without anyone needing to stop the line or touch the boards by hand.

Why PCB Storage Machines Are Essential in the SMT Process

In a busy SMT production line, not all machines move at the same pace. Some finish fast, others take more time. This difference in speed can create small traffic jams on the line. If one machine is waiting for another to catch up, you lose time. That's where a PCB storage machine really shows its value. It acts like a waiting zone, holding boards when needed and releasing them when the next machine is ready.

Take the pick-and-place machine and the reflow oven as an example. The pick-and-place machine might be loading components quickly, but the reflow oven takes longer to process each board. Without a buffer in between, boards could pile up or sit too long. A storage machine makes sure the handoff is smooth. It keeps everything in sync by adjusting the flow based on what's happening upstream and downstream.

This becomes even more important in high-speed, high-volume environments. When hundreds or thousands of PCBs are moving every hour, even a few seconds of delay adds up. Machines sitting idle or waiting around cost time and money. A storage system helps avoid these issues by balancing the flow. It's like a smart assistant that keeps the rhythm of production steady no matter what.

Manufacturers that run large batches or operate around the clock especially benefit from this. They need to prevent slowdowns and make sure every machine stays productive. Buffering gives them room to breathe—enough to handle small delays without stopping the entire line.

Key Functions and Features of PCB Storage Machines

PCB Buffering and Decoupling

A PCB storage machine acts like a flexible space between machines. It gives the front and back of the line some breathing room. That means even if the upstream machine is moving quickly or the downstream machine slows down, both can keep working. They don't have to stop for each other. This kind of decoupling keeps the entire process smoother and avoids unnecessary pauses.

Real-Time PCB Inventory Management

Knowing how many boards are on the line at any time helps avoid surprises. A good storage machine can track what's inside. It helps you see if boards are piling up or running low. This visibility makes it easier to plan and react quickly. Many machines even offer visual displays or software links so staff can monitor inventory without stopping production.

Physical and Electrostatic Protection

PCBs can be delicate. One bump or static shock could ruin them. Inside a storage machine, boards are kept in secure holders or on elevator tracks that prevent damage. Some machines also include ESD-safe features, like static shielding and soft-handling systems. This helps reduce damage during short-term storage, especially when no one's around to catch issues.

FIFO (First-In, First-Out) and Pass-Through Functions

Keeping the right processing order matters, especially when boards go through multiple steps. A FIFO setup ensures the first board in is the first one out. This keeps things fair and accurate. Some storage machines also allow pass-through mode. If the timing is just right, boards can go straight through without stopping. This feature boosts speed and efficiency when everything is in sync.

Advanced Control Systems

Behind the scenes, automation does most of the work. These machines usually run on a PLC system, which is like the brain that tells everything what to do. A servo lift helps move boards up and down with pinpoint accuracy. Photoelectric sensors detect the position of each board to avoid crashes. Many are also SMEMA-compatible, so they easily connect to other machines on the line. All of this tech working together makes the storage process fast, safe, and reliable.

Use Cases and Placement of PCB Storage Machines

PCB storage machines can be placed in several key spots on the production line. Each location helps solve a different flow problem. Knowing where to put these machines makes a big difference in how smooth the operation runs.

Between solder paste printer and pick-and-place machine

This is often the first spot where things can get out of sync. The solder paste printer might stop for cleaning, inspection, or paste refill. But if the pick-and-place machine is still running, it needs boards. A storage machine between these two keeps a small supply ready. If the printer takes a break, the line doesn't have to stop. And if the printer finishes a few boards faster than expected, the storage unit can hold them until the next step is ready.

Between pick-and-place machine and reflow oven

The pick-and-place machine is usually faster than the reflow oven. It can place parts quickly, but the oven takes time to heat and cool boards. That creates a slowdown. By placing a buffer in the middle, you avoid pileups. The storage machine holds finished boards until the oven is ready. It also prevents boards from sitting too long, which could affect solder quality. This gap helps control timing and board spacing before they go through heat.

Between AOI testing and subsequent assembly stages

After automatic optical inspection, some boards might be flagged for review or rework. Others move on right away. This can interrupt the flow. A storage unit after AOI keeps boards organized. If there's a delay while checking a few boards, the rest don't have to stop. It keeps good boards moving toward the next stage, whether that's manual assembly, final inspection, or packaging. It also helps avoid mixing up passed and failed boards, keeping the workflow clean and controlled.

Types of PCB Storage Machines and Their Applications

Different production setups call for different types of PCB storage machines. Some factories need high-speed handling, others care more about flexibility. Depending on your line, you might need something compact, something stackable, or something that fits a custom gap. Let's look at the common types and how they're used.

Lift-type PCB storage systems

Lift-type systems use an internal platform that moves up and down. It holds boards in slots or trays and lifts them into position when needed. These are great when you need tight control over how boards are released. A servo motor often powers the lift, giving it accurate, repeatable movements. You'll find these in places where timing matters or where space is limited but vertical room is available.

Magazine-type PCB storage machines

This type uses magazines, which are racks or frames that hold multiple boards. Machines push or pull PCBs in and out of the magazine automatically. It works well in high-volume lines or for storing boards between long process steps. Some units can hold several magazines at once. That means fewer interruptions and longer operation without manual restocking. They're popular in areas between AOI and reflow or as end-of-line buffers.

Modular vs. integrated buffering units

Modular units can be moved around and adjusted. They're handy when you want to test a new line setup or shift machines in the future. Integrated systems, on the other hand, are built into the line permanently. They often have tighter software connections and may run smoother since they're made to match nearby machines. The choice depends on whether you want more flexibility or more stability.

Custom dimensions and configurable options

Not all boards are the same size, and not all lines have the same spacing. That's why many PCB storage machines offer custom sizes. You can adjust things like the number of slots, board width, and even the direction boards flow—left to right or right to left. Some setups include touchscreen panels, smart sensors, or even data tracking features. These options help the machine fit your exact process without extra workarounds.

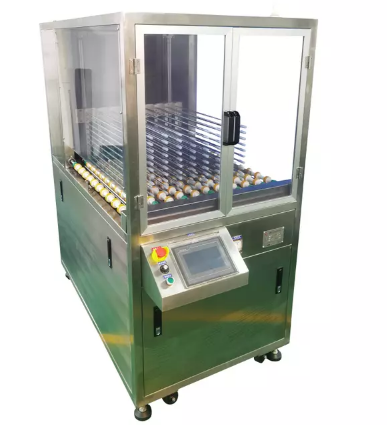

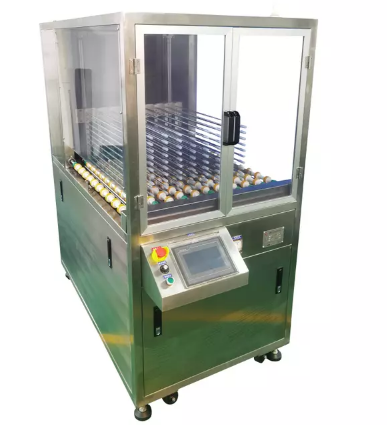

Meet Our PCB Temporary Storage Machine

PCB Temporary Storage Machine: Desiccant Storage Cabinet

When storing PCBs before assembly, moisture is a silent but serious threat. It can lead to corrosion, layer separation, and soldering issues that aren't always obvious until much later. That's why we offer the PCB Temporary Storage Machine, built specifically to protect boards from humidity and air exposure.

This system uses a desiccant-based method to maintain a dry, controlled environment inside the cabinet. It pulls moisture from the air and keeps humidity levels low—far below what typical storage rooms or open shelving can manage. The dry setting helps stop oxidation on solder pads and preserves the quality of sensitive surface finishes.

For facilities handling moisture-sensitive components or boards with immersion tin, ENIG, or HAL coatings, this cabinet is especially useful. It ensures the PCBs stay clean, dry, and ready for smooth soldering when needed. By maintaining this stable condition, it helps improve yield and reduce costly rework or scrapping of boards that absorbed too much moisture in storage.

Whether you're working with small batch runs or full-scale production lines, this storage solution supports consistent quality. It's a simple way to prevent unpredictable issues caused by poor storage conditions. If your goal is to run a tighter process and protect every board from the start, this unit earns its place on your floor. For further assistance, welcome to check our more of our supporting products.

Best Practices for Integrating a PCB Storage Machine

Planning for line layout and machine synchronization

Before adding a PCB storage machine to your line, it's smart to plan the layout carefully. You need to think about how each machine connects and how fast they run. If one device moves slower than the others, that's where buffering matters most. The storage unit should sit where delays happen, like before reflow or after inspection. When placed right, it helps keep all machines working in sync without waiting or jamming up the line.

Setting up proper operating conditions

Your environment plays a big part in protecting PCBs. Make sure the storage machine is placed in a clean zone. Try to avoid areas exposed to dust, airflow, or sudden changes in humidity. If possible, set it inside or near an ESD-safe area. That means proper flooring, grounding straps, and antistatic tools. Boards that sit inside the machine for more than a few minutes should be protected from electrostatic discharge and airborne particles.

Training staff on handling and interface usage

No matter how smart the machine is, people still need to use it right. That's why training is so important. Operators should know how to load and unload PCBs without touching sensitive areas. They also need to understand the control screen—how to pause, resume, and check the board count. Simple mistakes, like inserting boards backward or skipping touch-screen steps, can damage boards or slow down the line. Quick, clear training goes a long way.

Maintenance checklist and inspection intervals

Even the best machines need attention to stay reliable. Make a checklist for weekly and monthly inspections. Look at the sensors, belts, lift mechanism, and guide rails. Keep everything clean and lightly lubricated if needed. Check for dust buildup inside the track and confirm the emergency stop works. Also test the PLC system and make sure software settings match your current board type and thickness. Regular care reduces downtime and helps your machine last longer.

Common Mistakes to Avoid in PCB Storage

Overlooking humidity control

Moisture is one of the most damaging things for PCBs, yet it's often ignored. Without proper control, boards can absorb water from the air. That leads to corrosion, oxidation, and in extreme cases, delamination during soldering. Just because a room feels dry doesn't mean it's safe. Using dry cabinets, desiccant storage, or vacuum-sealed bags helps remove that risk. Humidity should be tracked—not guessed—especially in areas where boards sit for hours or days.

Storing boards in open air between process stages

Sometimes during busy shifts, operators leave PCBs sitting on racks or carts in the open. It seems harmless, but those few minutes can let in dust, static, and moisture. Even clean-looking environments carry risk. Boards should always go into protected storage or move directly to the next machine. Leaving them out exposes them to air particles that may interfere with later soldering or cause surface problems you won't see until testing fails.

Not using FIFO systems effectively

First-in, first-out matters more than people think. If older boards stay in storage too long, their solder surfaces may oxidize, especially on finishes like immersion tin or ENIG. Newer boards might get picked first just because they're closer, which leaves older ones aging out of spec. A proper FIFO system helps track what came in first. That means labels, tracking tools, and machines set up to release boards in order, not just based on position.

Skipping regular machine maintenance

It's easy to forget the storage machine when everything is running well. But ignoring it can lead to problems. Dust buildup, worn-out lift tracks, and uncalibrated sensors slowly make things worse. Eventually boards may jam or get misaligned. A small delay becomes a big one. Maintenance doesn't have to be complicated—just regular checks, quick cleaning, and some part inspections. Keep a schedule and stick to it before issues build up.

Conclusion

A PCB storage machine does more than just hold circuit boards—it keeps the entire production line moving smoothly. By managing flow between machines, it helps reduce downtime and prevent bottlenecks. It also protects boards from damage and ensures they're processed in the right order. With smart automation and proper setup, it boosts both output and quality. If you want better results from your electronics manufacturing process, it's worth exploring reliable PCB storage solutions.

FAQs

What is the main purpose of a PCB storage machine?

It acts as a buffer to manage timing differences between machines, preventing line stops and improving flow.

Where should PCB storage machines be placed on the line?

Common spots include between the solder paste printer and pick-and-place machine, or before the reflow oven.

How does a PCB storage machine protect boards from damage?

It uses features like photoelectric sensors and secure holders to prevent physical damage and reduce exposure to static.

Why is humidity control important in PCB storage?

Moisture can cause corrosion and soldering defects. Storage machines or cabinets help maintain a dry environment.

Can PCB storage machines support FIFO operation?

Yes, many models are designed to release boards in the order they entered, which helps maintain processing quality.