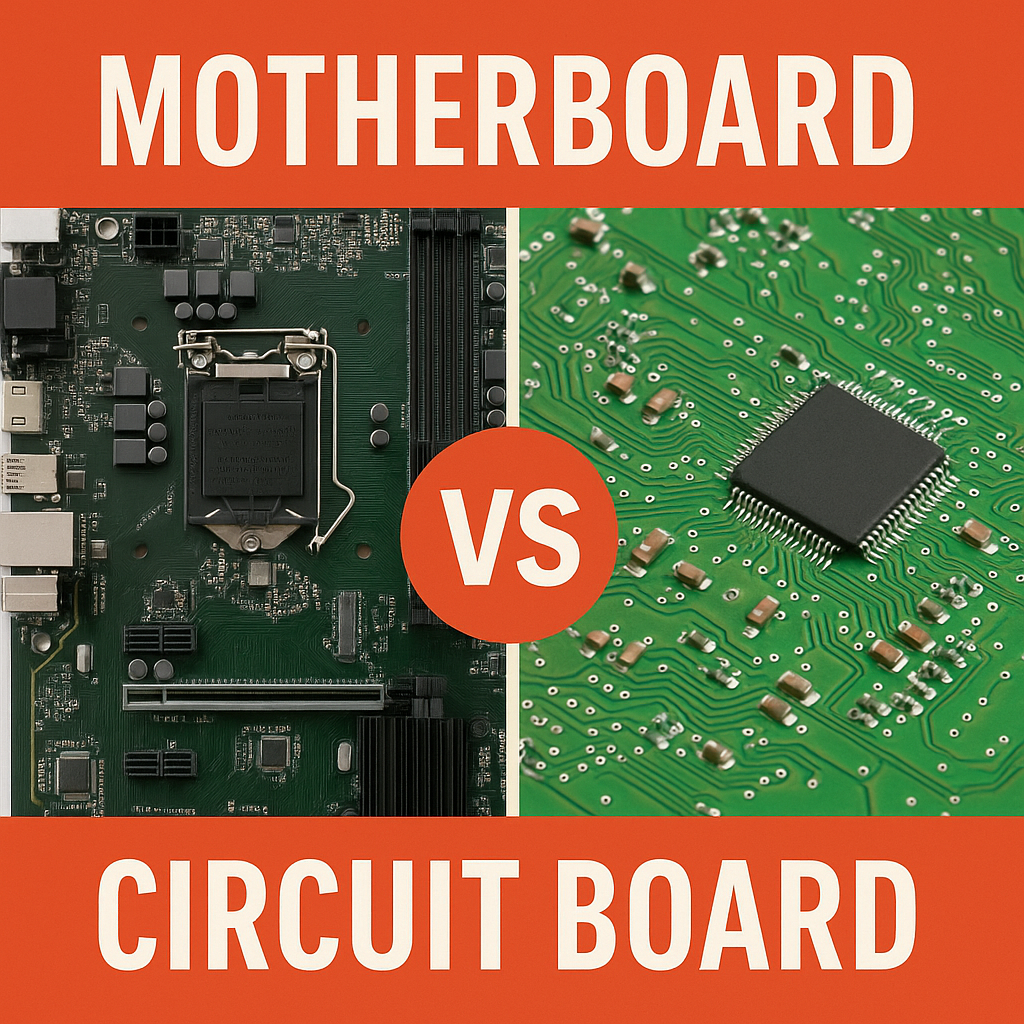

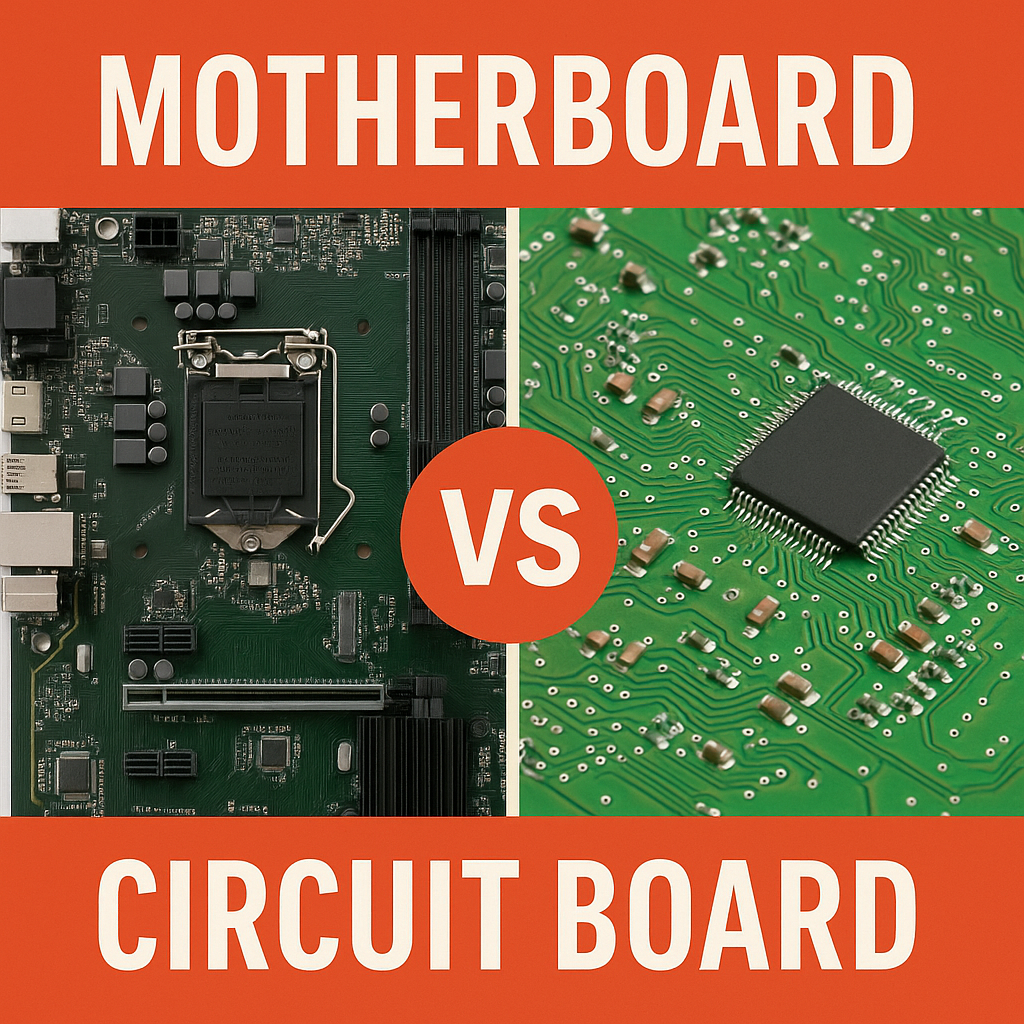

Ever wondered if a motherboard is just another type of circuit board? You're not alone—many people mix them up. But knowing the difference is key in electronics and computing.

In this post, we'll explain how motherboards and circuit boards differ in purpose, design, components, and cost. You'll also learn which one suits specific devices and why it matters in manufacturing.

What is a Circuit Board?

Definition and Purpose

A circuit board, often called a printed circuit board or PCB, is the backbone of nearly every electronic device we use today. It's a flat, solid board made from materials like fiberglass or epoxy. Thin copper paths are printed on its surface, and these act like tiny highways for electricity. Electronic parts—like resistors, capacitors, or chips—are mounted onto it, and the board connects them all together so they can work as a team.

You'll find circuit boards almost everywhere. They're in remote controls, smartphones, microwaves, toys, and even watches. Without them, devices couldn't power up, process signals, or carry out even the simplest actions. They're not just foundations—they're the nervous systems of electronics.

Common Types of Circuit Boards

Circuit boards come in many shapes, layers, and materials depending on what they're built for. Let's look at the most common ones:

Single-sided PCBs have components and copper traces only on one side. These are used in simple devices, like calculators or LED lights.

Double-sided PCBs use both sides of the board to place parts and run traces. With holes that connect one side to the other, they fit more complex circuits.

Multilayer PCBs stack three or more layers, separated by insulation. These are found in high-performance devices like smartphones or gaming consoles.

Rigid PCBs don't bend and are made for products that stay the same shape, like TVs or routers.

Flexible PCBs are made from bendable materials, so they fit into tight or curved spaces—think of foldable phones or fitness bands.

Rigid-Flex PCBs combine parts that bend with parts that don't. These are used in things like cameras or medical devices, where space is tight and reliability is critical.

High-frequency PCBs are built for very fast signal transmission. You'll see these in radar systems or wireless communication tools.

Aluminum and ceramic PCBs are designed to handle heat. They're common in LEDs, power converters, or high-power industrial equipment.

Applications Beyond Computers

Circuit boards are way more than just computer parts. Sure, motherboards are circuit boards too, but this technology spreads across countless industries.

In healthcare, circuit boards power diagnostic machines, heart monitors, and handheld tools. In factories, they help control machines, monitor systems, and automate tasks. We even use them in vehicles—for controlling sensors, brakes, and navigation systems. They're inside your washing machine, your smart thermostat, and even that electronic toy sitting on the floor.

Wherever there's electricity and control, there's probably a circuit board doing the work behind the scenes.

What is a Motherboard?

Definition and Role

A motherboard is the main circuit board inside a computer. It acts like the control center where everything connects. Without it, none of the computer's parts would be able to work together. It holds the CPU, memory, storage connections, graphics cards, and ports for all kinds of devices.

You can think of it as the body's central nervous system. The CPU is the brain, and the motherboard helps all the other parts talk to that brain and to each other. It also distributes power, stores system settings, and controls startup processes.

Components Found on a Motherboard

A typical motherboard includes many different parts, each playing a role in how the system performs:

The CPU socket is where the processor gets installed. It's usually the largest and most central spot on the board.

RAM slots hold memory modules, often two or four depending on the board size.

PCIe slots are long and thin. They let users plug in things like graphics cards or sound cards.

SATA and M.2 connectors are for storage devices like SSDs or hard drives.

Power connectors link the board to the power supply unit. The biggest one is the 24-pin main power, and there's often another for the CPU.

I/O ports line the back edge and provide USB, Ethernet, audio, and video connections.

Other parts include the BIOS or UEFI chip that stores basic settings, and VRMs that help regulate power for the CPU.

Each piece works together to make sure the computer can boot, run programs, and handle everything from browsing to gaming or video editing.

Form Factors and Their Uses

Motherboards come in different shapes and sizes, called form factors. Each one fits different kinds of computer cases and use cases:

ATX boards are the most common for desktop PCs. They're full-sized, with lots of room for expansion cards, RAM slots, and cooling systems.

MicroATX boards are smaller but still powerful. They're often used in budget builds or compact desktops where saving space matters.

Mini-ITX boards are the smallest of the standard options. Perfect for small form factor PCs, they usually have fewer ports and only one expansion slot.

E-ATX boards are larger than standard ATX. These are built for high-end users who need more space for multiple GPUs or heavy workloads.

Choosing the right form factor depends on how much performance and flexibility the build needs, and how much physical space is available.

Motherboard vs Circuit Board: Side-by-Side Comparison

Key Differences

Even though a motherboard is technically a type of circuit board, it's not just another one in the crowd. It's built for a very specific job—managing every critical component in a computer. On the flip side, circuit boards show up everywhere, from microwave ovens to digital watches. They can be super simple or pretty advanced depending on the task.

Let's take a quick look at how they compare:

| Feature | Motherboard | Circuit Board |

| Function | Central hub for computing systems | Base for general electronic component connection |

| Complexity | Very high | Ranges from simple to complex |

| Expandability | Highly modular | Typically fixed-purpose |

| Cost | Higher due to complexity | Lower (generally) |

| Application | Computers (PCs, laptops, servers) | Any electronic device |

A motherboard is usually packed with sockets, slots, and connectors to allow upgrades or replacements. It's built to evolve with the system it supports. Most other circuit boards are designed once and stay as they are.

Circuit boards might be single-layered for a toy or multi-layered for a smartphone. Motherboards are always multi-layered because of how many tasks they manage and how many signals they route.

Summary Analogy

Think of a motherboard like a custom-built command center. Everything around it depends on its structure, layout, and connections. It's designed specifically for computers and knows exactly what it needs to handle.

Now picture a circuit board as a versatile worker. It can fit into nearly any electronic job, from powering a speaker to controlling an electric fan. It might not do everything, but it's everywhere and incredibly adaptable.

Why Are Circuit Boards and Motherboards Green?

Ever opened up an electronic device and wondered why the board inside is almost always green? It's not just for looks. That color actually comes from a protective layer called the solder mask. This mask covers the copper traces to prevent short circuits, corrosion, and physical damage. While solder masks can come in many colors, green became the go-to choice early on.

Part of the reason is tradition. Back when PCBs were first being mass-produced, green epoxy resin worked really well. Over time, it became the standard. Manufacturers got used to it. So did repair technicians, engineers, and even designers. That comfort led to wide adoption, and now most people just expect circuit boards to be green.

Green also helps with visibility. It creates a sharp contrast for white or yellow silkscreen labels printed on the board. These labels show where components go or what they do. When techs build or inspect a board, clear markings make their jobs easier and faster.

From a cost perspective, green solder mask is also efficient to produce. The materials are available in bulk. Production lines are optimized for it. Trying another color? It could cost more and slow down manufacturing.

So while there's no rule saying circuit boards must be green, the color sticks around because it's reliable, readable, and budget-friendly.

Introducing: Double Sided Precision Exposure Machine for PCB

Product Highlight

In the production of modern circuit boards, precision exposure is one of the most important steps—especially when dealing with multilayer or fine-pitch designs. That's where the Double Sided Precision Exposure Machine for PCB comes in. It's built for advanced needs like PCB and FPC manufacturing, graphic pattern alignment, and solder mask exposure on flat surfaces.

This machine offers dual-sided exposure, which means both sides of the board can be processed at once. That speeds things up while also improving alignment accuracy. It's especially useful for making dense circuit designs found in smartphones, medical electronics, or compact computing systems.

What sets it apart is how easy it is to use. The interface is simple enough for new operators to pick up quickly, but powerful enough to support large production runs. It doesn't demand much maintenance either, which saves time and costs on the factory floor.

Here's what users can expect:

Precision alignment across both sides of the board

Clean image definition for tiny circuits and solder masks

Smooth operation through a user-friendly control system

Reliable performance even during long production shifts

Whether the goal is to improve exposure speed or meet stricter quality demands, this machine helps manufacturers handle complex PCB layers with more confidence and less hassle.

When to Use Which: Circuit Board or Motherboard?

Questions to Ask

Choosing between a circuit board and a motherboard starts with a few simple questions. First, what exactly will the device do? If you're designing something that reads sensor data or controls lights, you probably don't need the extra features of a motherboard.

Next, think about whether the device needs a CPU, RAM, or room for future upgrades. Devices like computers or servers need all of those, which makes a motherboard the clear choice. But a smart thermostat or LED controller likely runs on a simpler setup.

Also ask: are you building a computer or something entirely different? If it's a PC, laptop, or server, a motherboard isn't optional. For anything else—from fitness trackers to washing machines—a smaller, customized circuit board might do the job better and cheaper. For further needs, just check out our products.

Use Case Scenarios

Circuit boards are perfect when space is limited, or when the device only performs one or two tasks. You'll see them in:

IoT gadgets like smart doorbells or sensors

LED lighting systems with basic control boards

Wearables or portable electronics that don't need modular parts

On the other hand, motherboards work best when flexibility and power are needed. They're ideal for:

Desktop computers and custom-built PCs

Gaming systems where GPU slots and RAM upgrades matter

Workstations or servers that manage heavy multitasking and data flow

Conclusion

Knowing the difference between a motherboard and a circuit board helps you make better choices when working with electronics. A motherboard is a specific, complex type of circuit board used in computers. Circuit boards, though, are everywhere—from microwaves to mobile devices. They come in all shapes, sizes, and layers. Once you understand how they work and what each one does, it's easier to design, repair, or upgrade your projects.

FAQs

1. Is a motherboard the same as a circuit board?

Not exactly. A motherboard is a special kind of circuit board used mainly in computers. Circuit boards are more general and found in all sorts of devices.

2. Can I use a regular circuit board instead of a motherboard?

No. Only a motherboard can connect and manage complex computer parts like the CPU, RAM, and storage.

3. Why are most circuit boards green?

They're green because of the solder mask used during manufacturing. Green became a standard due to visibility, tradition, and cost.

4. What are common devices that use circuit boards but not motherboards?

Things like remote controls, LED lights, calculators, and sensors often use circuit boards without needing a full motherboard.

5. What makes motherboards more expensive than basic circuit boards?

Motherboards are more complex. They include extra features like CPU sockets, expansion slots, and power regulators, which raise the cost.